The Foundation of Industry and Modern Civilization - An Exploration

Metals, a class of materials characterized by their strength, ductility, malleability, conductivity, and luster, have been fundamental to human progress and the development of civilization. From the earliest tools and weapons to the complex machinery and infrastructure of the modern world, metals have played a pivotal role in shaping our societies and driving technological advancements. Their unique properties have made them indispensable in countless applications, from construction and manufacturing to electronics and medicine.

1. Properties of Metals: Characteristics that Define Their Usefulness

Metals possess a unique combination of properties that make them incredibly useful:

- Strength: Metals are generally strong and durable, able to withstand significant force and stress.

- Ductility: Many metals can be drawn into wires without breaking.

- Malleability: Many metals can be hammered or pressed into sheets without breaking.

- Conductivity: Metals are excellent conductors of heat and electricity.

- Luster: Metals typically have a shiny or lustrous appearance.

- High Melting and Boiling Points: Most metals have high melting and boiling points.

- Density: Metals are generally denser than nonmetals.

- Sonorous: They produce a ringing sound when struck.

2. Types of Metals: A Diverse Range of Elements

The term "metal" encompasses a wide range of elements, which can be broadly classified into several categories:

- Ferrous Metals: Metals that contain iron as their primary constituent.

- Steel: An alloy of iron and carbon, known for its strength and versatility. There are many different types of steel such as carbon steel, stainless steel, and tool steel.

- Cast Iron: An iron-carbon alloy with a higher carbon content than steel, known for its hardness and brittleness.

- Non-Ferrous Metals: Metals that do not contain significant amounts of iron.

- Aluminum: Lightweight, corrosion-resistant, and highly conductive.

- Copper: Excellent conductor of heat and electricity, also corrosion-resistant and malleable.

- Zinc: Often used for galvanizing, which is the process of applying a protective zinc coating to steel or iron, to prevent rusting.

- Tin: Used in solders and for plating.

- Lead: Historically used in plumbing, batteries, and other applications. Use is declining due to toxicity.

- Nickel: Often used in alloys such as stainless steel.

- Titanium: Strong, lightweight, and corrosion-resistant, often used in aerospace applications.

- Precious Metals: Rare, naturally occurring metallic elements of high economic value.

- Gold: Highly malleable, ductile, and corrosion-resistant, used in jewelry, electronics, and as a store of value.

- Silver: Excellent conductor of electricity, used in jewelry, electronics, and photography.

- Platinum: Dense, malleable, ductile, and highly unreactive, used in jewelry, catalytic converters, and laboratory equipment.

- Alloys: Mixtures of two or more metals, or a metal and a nonmetal, designed to have specific properties.

- Brass: An alloy of copper and zinc.

- Bronze: An alloy of copper and tin.

- Stainless Steel: An alloy of iron, chromium, and often nickel that is resistant to corrosion.

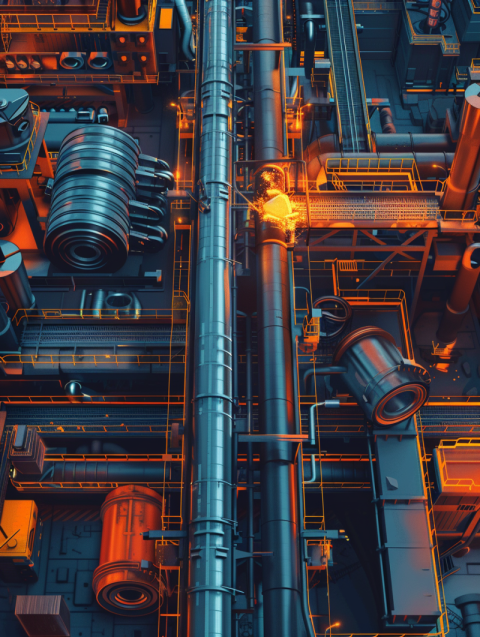

3. Extraction and Processing of Metals: From Ore to Finished Product

The process of obtaining metals from their natural sources and transforming them into useful products involves several stages:

- Mining: Metal ores are extracted from the earth through various mining techniques, such as open-pit mining or underground mining.

- Beneficiation/Ore Dressing: This process concentrates the valuable minerals in the ore and removes unwanted materials (gangue).

- Smelting: A process that uses heat and a chemical reducing agent to decompose the ore, driving off other elements as gases or slag and leaving just the metal behind.

- Refining: Further purification of the metal to remove impurities.

- Alloying: Mixing the metal with other metals or nonmetals to create alloys with desired properties.

- Forming: Shaping the metal into desired forms through processes like casting, rolling, forging, and extrusion.

- Finishing: Treating the surface of the metal to improve its appearance, durability, or other properties.

4. Applications of Metals: Shaping Our World

Metals are used in a vast array of applications, including:

- Construction: Steel, aluminum, and copper are used in buildings, bridges, and other infrastructure.

- Transportation: Metals are essential for manufacturing cars, airplanes, trains, and ships.

- Manufacturing: Used to make machinery, tools, and countless other products.

- Electronics: Copper, gold, silver, and aluminum are crucial components of electronic devices.

- Packaging: Aluminum and tin are used in food and beverage packaging.

- Medicine: Surgical instruments, implants, and other medical devices are often made of metals like stainless steel and titanium.

- Jewelry: Gold, silver, and platinum are prized for their beauty and used in jewelry making.

- Energy: Used in power generation, transmission, and storage.

5. The Importance of Metals in Society: Driving Progress and Innovation

Metals have been instrumental in the advancement of human civilization:

- They have enabled the development of tools, weapons, agriculture, transportation, and countless other technologies.

- Metals are essential for modern infrastructure, manufacturing, and communication systems.

- They play a crucial role in economic development and global trade.

6. Recycling of Metals: Sustainability and Resource Conservation

Recycling metals is crucial for environmental sustainability and resource conservation:

- Recycling metals reduces the need for mining, which can have significant environmental impacts.

- It also conserves energy, as recycling metals typically requires less energy than producing them from raw materials.

- Many metals, such as aluminum, steel, and copper, can be recycled repeatedly without losing their properties.

7. Challenges and Innovations in the Metal Industry

- The metal industry faces challenges related to resource depletion, environmental impacts, and fluctuating metal prices.

- There is ongoing research and development into new alloys, processing techniques, and applications for metals.

- The development of lighter, stronger, and more durable metals is a key area of focus.

- The use of metals in 3D printing and other advanced manufacturing processes is expanding.

8. The Future of Metals

- Metals will continue to play a vital role in shaping our world, driving technological advancements and enabling new innovations.

- The demand for metals is expected to grow, particularly in emerging economies.

- Sustainability and resource efficiency will be increasingly important considerations in the metal industry.

- Nanotechnology is being used to manipulate the structure of metals at the atomic level.

Conclusion:

Metals are fundamental to modern civilization, underpinning our infrastructure, transportation systems, manufacturing processes, and countless everyday objects. Their unique properties, coupled with human ingenuity, have enabled remarkable technological advancements and shaped the course of history. As we move forward, the sustainable and responsible use of metals will be crucial for meeting the needs of a growing global population while minimizing environmental impact. The ongoing development of new alloys, processing techniques, and applications ensures that metals will continue to play a vital role in shaping our future.

Metal, metals, types of metals, properties of metals, ferrous metals, non-ferrous metals, precious metals, steel, aluminum, copper, gold, silver, platinum, titanium, zinc, tin, lead, nickel, metal alloys, brass, bronze, stainless steel, metal extraction, mining, smelting, refining, metal forming, metal finishing, metal recycling, metal uses, metal applications, metal in construction, metal in transportation, metal in electronics, metal in medicine, metal in jewelry, metal prices, metal industry, metal manufacturing, metal suppliers, metal fabrication, metal ores, metal properties explained, metal corrosion, rust.